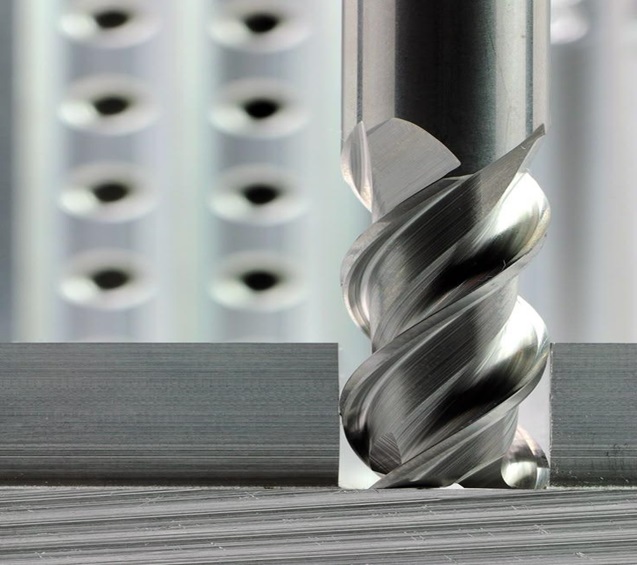

Your production line runs longer when your industrial milling media gets regular care. Start with a fast visual check at the start and end of each shift. Look for color changes, chips, and flat spots. Log noise and vibration from the mill so you know what normal sounds like. Small changes often point to bigger issues you can fix early.

Screen and gauge your grinding media on a set schedule. Use a simple stack of sieves to track size distribution. Replace outliers that fall below your minimum and top up with fresh charge to keep fill level steady. Measure bulk density in a small bucket and compare it to your baseline. A lighter reading can indicate wear or trapped fines that slow throughput.

For vibratory bowls and barrels, inspect your tumbling media after each batch. Rinse and separate parts from media fully. Run a magnet sweep when ferrous chips are possible. Check shapes for rounding that hurts cutting action. Keep a record of cut rate and finish quality for each recipe. When finishing quality drifts, verify speed, load, and water or compound ratios before you blame the media.

Protect downstream equipment by controlling fines that can reach a catalyst bed or sensitive process stage. Fit screens, magnets, and simple bag filters where discharge leaves the mill. Vacuum dust at changeovers. Keep separate bins for different materials to avoid mix ups. If you process both metal and ceramic parts, clean the line fully between runs to avoid trace carryover that can foul high value products.

Moisture and corrosion shorten the life of stainless steel tumbling media. Drain and dry bowls at the end of the day. Wipe down contact surfaces and leave lids open to vent. If you see orange staining, run a short passivation cycle using the compound your supplier recommends. Store media in breathable containers off the floor and away from cool walls to reduce condensation.

Daily checks that prevent drift

Walk the line with a short checklist. Verify guards and covers. Confirm water or compound flow in wet processes. Listen for rubbing or scraping. Feel the motor housing and bearings for unusual warmth. Spot clean spills so slurry does not harden on moving parts. These habits take minutes and prevent hours of cleanup and downtime.

Weekly sizing and density control

Create a simple routine for sample pulls. Take a measured scoop at the same time each week and run a sieve test. Note the percent in each size range. Compare the curve to last month. If the curve shifts, adjust make-up quantity or switch to a harder grade before finish quality drops. Track bulk density with the same container and scale. Consistency builds trust in your data.

Liner and machine health

Media life depends on the health of liners, bowls, barrels, and screens. Inspect liners for grooves and lift points that trap pieces. Check screen tension and look for broken wires. Tighten loose fasteners. Grease bearings on the vendor schedule. Verify mill speed with a tach and compare it to the nameplate. A small loss in speed can show up as longer cycles and more wear.

Cleanliness and cross contamination control

Clean equipment between materials. Drain slurry. Rinse with clean water. Run an empty cycle with a cleaning compound if you process soft alloys after hard steels. Use labeled scoops and storage bins. Keep media off the floor and away from oils. A clean room prevents grit in seals and keeps finish consistent from batch to batch.

Storage handling and changeout discipline

Store fresh and used media separately. Rotate inventory so older lots go first. During changeout, separate good pieces from fines with a screen. Discard pieces that fall below your minimum size or show cracks. Top up by weight to your standard fill. Record the date, weight removed, weight added, and reason. This history helps you forecast cost and plan purchases.

Data tracking that drives better decisions

Build a one page log for each mill or bowl. Include cycle time, load, energy draw, noise notes, density, and size curve highlights. Add a simple chart for cycle count since last top up. Set green and red bands for each metric. When a value crosses a line, take action and write what you did. Over time you will see which actions extend life and which do not move the needle.

Operator training that keeps routines on track

Train your team to spot early signs of trouble. Show real samples of chipped and glazed media. Teach safe sampling and screening. Explain why fill level and speed matter. Give each operator clear ownership for daily and weekly tasks. Make the checklist quick and visible at the machine. Praise tight logs and clean stations. People keep what they understand and own.

Quality tests that protect parts

Run a short witness test after big changeouts. Process a set of coupons and measure surface finish. Check edges for burrs and dents. If the finish looks off, pause and review your last changes before you run production parts. Keep a small library of past coupons with notes. Side by side comparisons help you decide fast and reduce scrap.

Root cause thinking when issues appear

When life drops or finishes degrades, resist the urge to swap media first. Ask what changed. New batch of compound. Warmer room. Heavier loads. Slower speed. One change at a time with a quick test saves money and gives clear answers. If you need help, call your vendor with your logs. Good data leads to good advice.

Simple starter checklist

- Start and end of shift walk and clean.

- Weekly sieve and density check with logs.

- Monthly liner and screen inspection with fixes.

- Changeout with sort, top up by weight, and record.

- Witness coupons after major changes.

Action wrap

Pick one routine to tighten this week and write it into a one page checklist. Run it for two weeks and review the data with your team. Keep what works and expand from there. Your media lasts longer. Your parts stay safe. Your line runs smoother.

Comments